Your coolant for sustainable cooling and freezing processes

CFC, HCKW, glycol free

Non-toxic and not explosive

Easily biodegradable (COD = 0.095)

Global Warming Potential (GWP) = 0

Ozone depletion potential (ODP) = 0

HYCOOL 50, HYCOOL 45, HYCOOL 20, HYCOOL Blue

HYCOOL is a modern and non-toxic low-temperature heat transfer fluid and is use in the secondary circuit of indirect cooling systems.

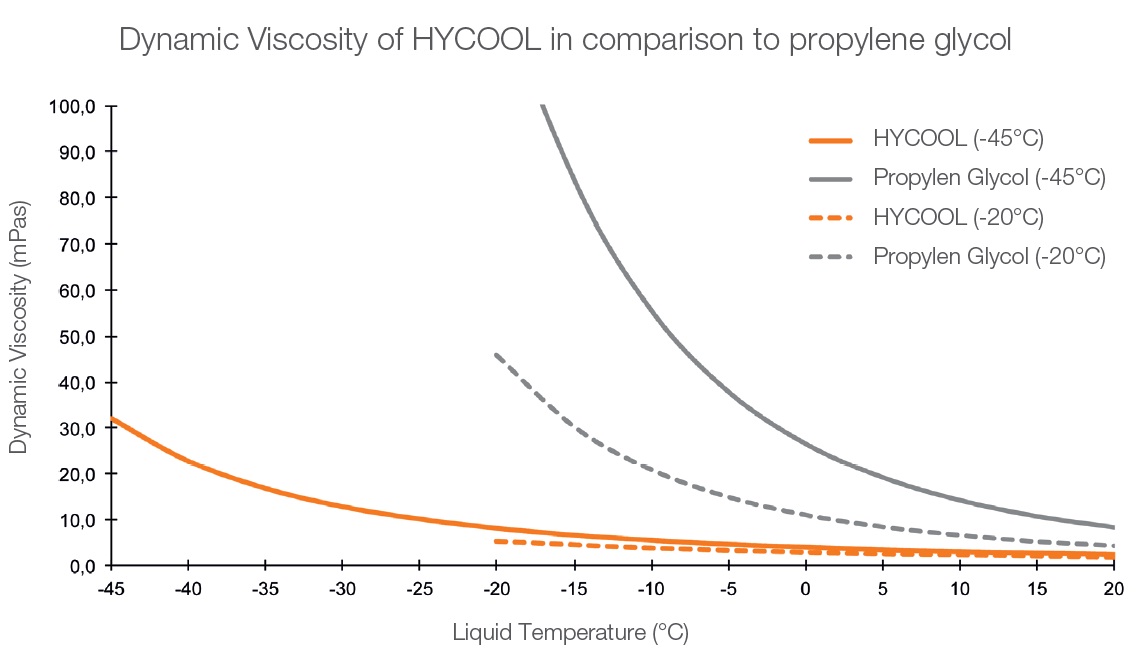

The advantages of HYCOOL are a low freezing point, outstanding thermodynamic properties (high thermal conductivity), a low viscosity, a high level of environmental compatibility and good material compatibility with all common metals and polymers.

The low freezing point of HYCOOL enables it to be used in systems that operate in temperature ranges down to -50 ° C (burst protection down to -60 ° C).

HYCOOL – 3 qualities for demanding applications

HYCOOL is available in three different, ready-to-use formulations – trailor-made for the requirements of our customers:

HYCOOL 20

HYCOOL 45 and

HYCOOL 50

The number refers to the freezing point of the heat transfer medium (e.g. HYCOOL 20 freezes at -20 ° C).

ADDCON continues to offer HYCOOL Blue. This is a dye for HYCOOL that makes it easy to identify leaks.

HYCOOL stands for

Environmentally friendly and biodegradable

Non-toxic and food safe, even in larger quantities

Non-flammable and not explosive

Low viscosity and excellent thermodynamic properties ensure a high COP

Reliable and long-term chemically stable

Compatibility with all common metals and polymers

Low operating pressure of the systems

HYCOOL – the success story

HYCOOL's success story began over 15 years ago. Today customers with demanding and critical applications all over the world trust their systems operated with HYCOOL. Companies that use HYCOOL as a secondary refrigerant in their systems can be found in the food and beverage industry, retail and wholesale, the pharmaceutical industry, the chemical industry, shipping and other areas that focus on sustainable and reliable cooling and freezing processes are instructed.

HYCOOL – Potential savings and additional benefits

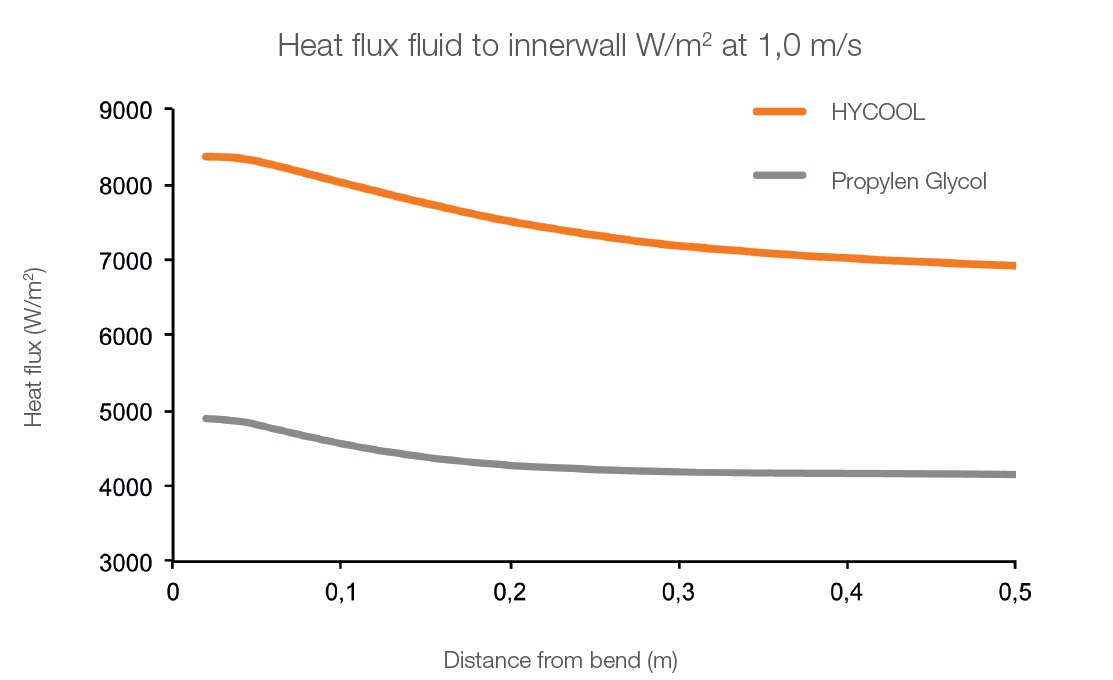

Secondary cooling systems that are operated with HYCOOL generate considerable energy saving potential through outstanding thermodynamic properties.

improved efficiency of the systems and lower energy consumption Energy savings of up to 20% enable.

Increased number of cooling cycles

smaller size of the systems

However, the long-term stability, which enables a long service life of the systems with low repair and maintenance costs, minimizes the LCC (Life Cycle Costs) over the entire life of the systems. Compared to glycol, the use with HYCOOL has much lower LCC. The LCC consist of the running costs and the investment costs. The energy used for cooling and air conditioning in Germany was 14% of the total energy consumption in 19995. This number shows how important it is to save energy, especially in the area of "cooling". Additional doors on cooling shelves are one way to save energy - another is to improve the efficiency of the cooling system. In addition to the low energy consumption of HYCOOL cooling systems, these systems produce "free" heat, which in Underfloor heating or for easy defrosting of the systems can be used. This is a modern and sustainable way to recycle heat while saving money and protecting the environment.

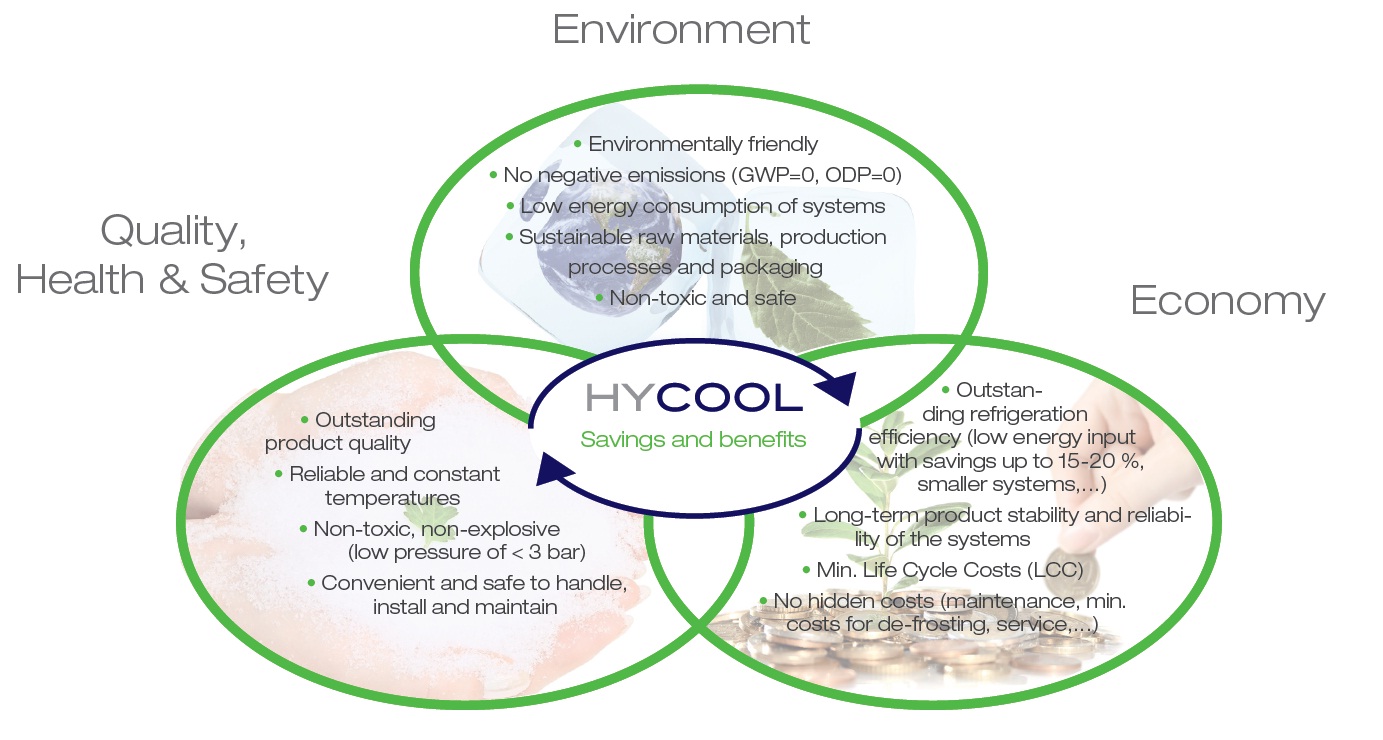

HYCCOLs comprehensive approach to sustainability

This sustainability approach not only takes environmental aspects into account, but also pursues a comprehensive analysis that takes into account environmental aspects as well as efficiency and cost aspects as well as safety concerns.

Thanks to these unique product properties, HYCOOL offers the industry a product that meets both today's high demands on application properties and the increasing demand for sustainable and safe products.

This makes HYCOOL the preferred coolant in secondary cooling systems.

HYCOOL – User

Food industry

Processors and food producers need constant temperatures and trust in their reliable and efficient HYCOOL cooling systems. The fact that HYCOOL is also non-toxic enables the production of fresh and safe food of the highest quality. the food processing industry.

Beverage production

HYCOOL plays a crucial role in the production of milk products, beer, wine or juices. The achieved Energy savings through the use with HYCOOL enable more efficient production processes and save money.

Refrigerator operators

Operators of cold rooms for meat, fish or dairy products need exact and constant temperatures and reliable Cooling systems. The safety and reliability of the systems operated with HYCOOL are particularly valued during the storage of perishable goods. Operators of cold rooms for fruit and vegetables also appreciate the constant temperatures achieved by cooling with HYCOOL. The result of storing fruits and vegetables in air-conditioned cold rooms using HYCOOL are fruits and vegetables that have the quality of freshly harvested goods even after a long storage period.

Freezer operators

Freezing processes must have precise temperature profiles and constant temperatures in order not to impair the quality of the goods. Freezing systems that are operated with HYCOOL reliably freeze at the desired temperatures.

Warehouse operator

Large warehouses for the storage and distribution of different and sometimes perishable goods require constant ones

Temperatures throughout the building. Cooling these devices requires a large amount of energy. Operators of these warehouses appreciate the energy savings achieved through HYCOOL.

Wholesale and retail- counters, shelves and cold rooms

The operation of refrigerated shelves or counters in supermarkets is a special challenge. The systems are either permanently open or are opened regularly - however, defined temperatures must be maintained. HYCOOL fulfills these constant temperature ranges, therefore guarantees food safety and at the same time saves 15-20% energy. By using HYCOOL, users can minimize their CO2 emissions and demonstrate environmental awareness.

Chemical industry

Large capacity refrigeration and freezing processes are needed in various industries. These systems must be safe and must not pose any danger, for example from explosive gases, in the plants. HYCOOL fulfills these high requirements and is therefore the right coolant for different, demanding applications in the industrial sector.

Pharmaceutical industry

Various pharmaceutical products must be refrigerated or frozen in order not to impair the quality or safety of the products. The pharmaceutical industry relies on systems that are operated with HYCOOL and appreciates the safety and non-toxicity of this unique refrigerant.

Shipping

Cruise ships and fishing boats trust their systems operated with HYCOOL. These systems maintain all areas on board that require cooling or freezing processes: from all freezing and cooling applications to air conditioning systems to cooling pool water. HYCOOL is environmentally friendly and biodegradable and poses no danger as it is neither flammable nor explosive is. These are the reasons why HYCOOL is the preferred refrigerant in shipping.

Ice rinks and indoor ski areas

Operators of ice rinks and ski halls in all climate regions of the world prefer HYCOOL as a coolant. The capital and energy intensive freezing processes benefit from energy savings of 15-20%, which are achieved by HYCOOL. Additional benefits such as biodegradability, non-toxicity and non-explosiveness are properties of HYCOOL that can be communicated to demonstrate corporate responsibility.

Heat pumps & solar thermal

The use of HYCOOL in heat pumps and solar thermal systems supports the environmental concept of these applications. The use of HYCOOL in these areas means that there is no need to compromise between efficiency and environmental sustainability.

Good to know

To ensure that all products meet the high requirements of our customers, ADDCON produces according to comprehensive quality standards. The entire production for HYCOOL fully meets the requirements of DIN EN ISO 9001: 2008.

ADDCON Nordic offers advice and chemical analysis of HYCOOL samples. Persons who come into contact with HYCOOL should be informed about and have access to the recommended safety precautions. The data contained in this document are based on studies and experience and have been summarized to the best of our knowledge and belief. External factors during the use of HYCOOL can neither be influenced nor taken into account by ADDCON NORDIC AS. Therefore, product data published for HYCOOL cannot be used to guarantee or guarantee claims against ADDCON NORDIC AS to assert.

Technical specifications

Composition:

Potassium formate 30 - 50%, deionized water, corrosion inhibitor

pH:

10,6 – 11,4

Freezing point:

-20 to -50 ° C (depending on HYCOOL quality)

Density / specific density:

1194 - 1348 kg / m³

Dynamic viscosity: (at 20 ° C)

1.8 - 2.6 mPas (cP)

Specific heat capacity: (at 20 ° C)

2.5 - 3.0 kJ / kgK

Packaging:

IBC container (1,000 liters)

Loose goods (silo truck)

Please contact us if your desired container size is not listed. Thanks to flexible production structures and short decision-making processes, we are happy to implement customer requests.

Production & delivery:

HYCOOL is produced by ADDCON NORDIC AS in Porsgrunn, Norway. ADDCON NORDIC is a subsidiary of the German-based ADDCON GmbH. ADDCON GmbH specializes in the development and production of sustainable product solutions for industry and agriculture -

in short: "green" chemistries.

Metals compatible with HYCOOL

• copper

• Brass

• Carbon steel

• stainless steel

• cast iron

• aluminum

• magnesium

• Soldering stick

• Silver solder

Metals, not compatible with HYCOOL

• Galvanized steel

• zinc

• solder

Furthermore, HYCOOL does not damage any sealing materials that are commonly used in cooling systems.

Polymers compatible with HYCOOL

• LDPE soft polyethylene

• HDPE hard polyethylene

• PP polypropylene

• PTFE polytetrafluoroethylene

• PA * polyamide

• PVC polyvinyl chloride

• PPO polyphenylene oxide

• PMMA polymethyl methacrylate

• PES polyethersulfone

• Aramid Aromatic polyamide

• ABS acrylonitrile butadiene styrene

• EP epoxy resins

• NBR nitrile rubber

• UP Unsaturated polyester resins

• PMMA acrylate

• CR chloroprene rubber (neoprene)

• NBR nitrile rubber

• EPDM Vulcanized ethylene propylene diene monomer

• SBR vulcanized styrene-butadiene rubber

• MVQ silicone rubber

• IIR butyl rubber

* Compatible below 40 ° C

Polymers, not compatible with HYCOOL

• FPM fluorocarbon rubber (Viton)